- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Material: | |

|---|---|

| Availability: | |

| Quantity: | |

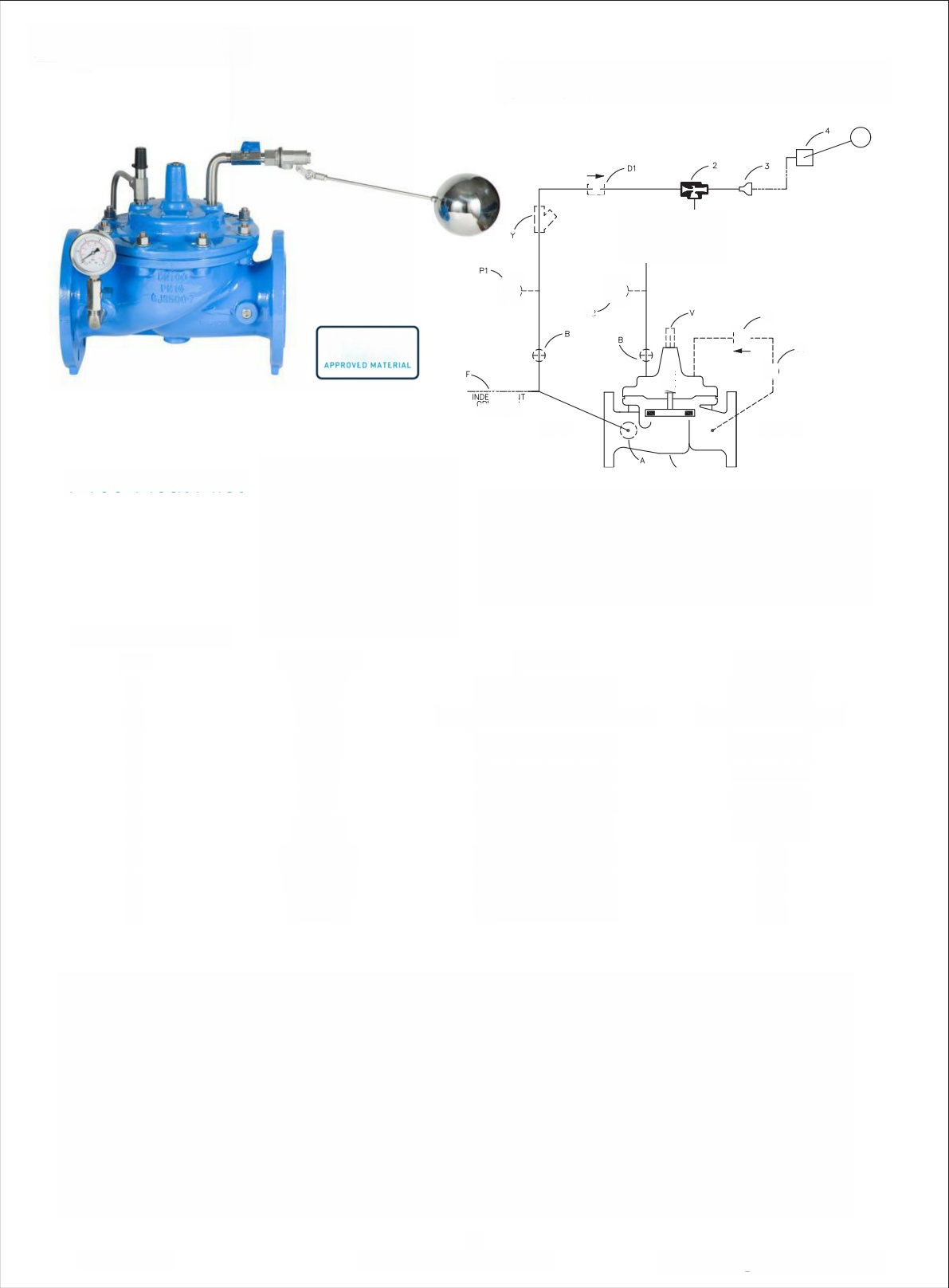

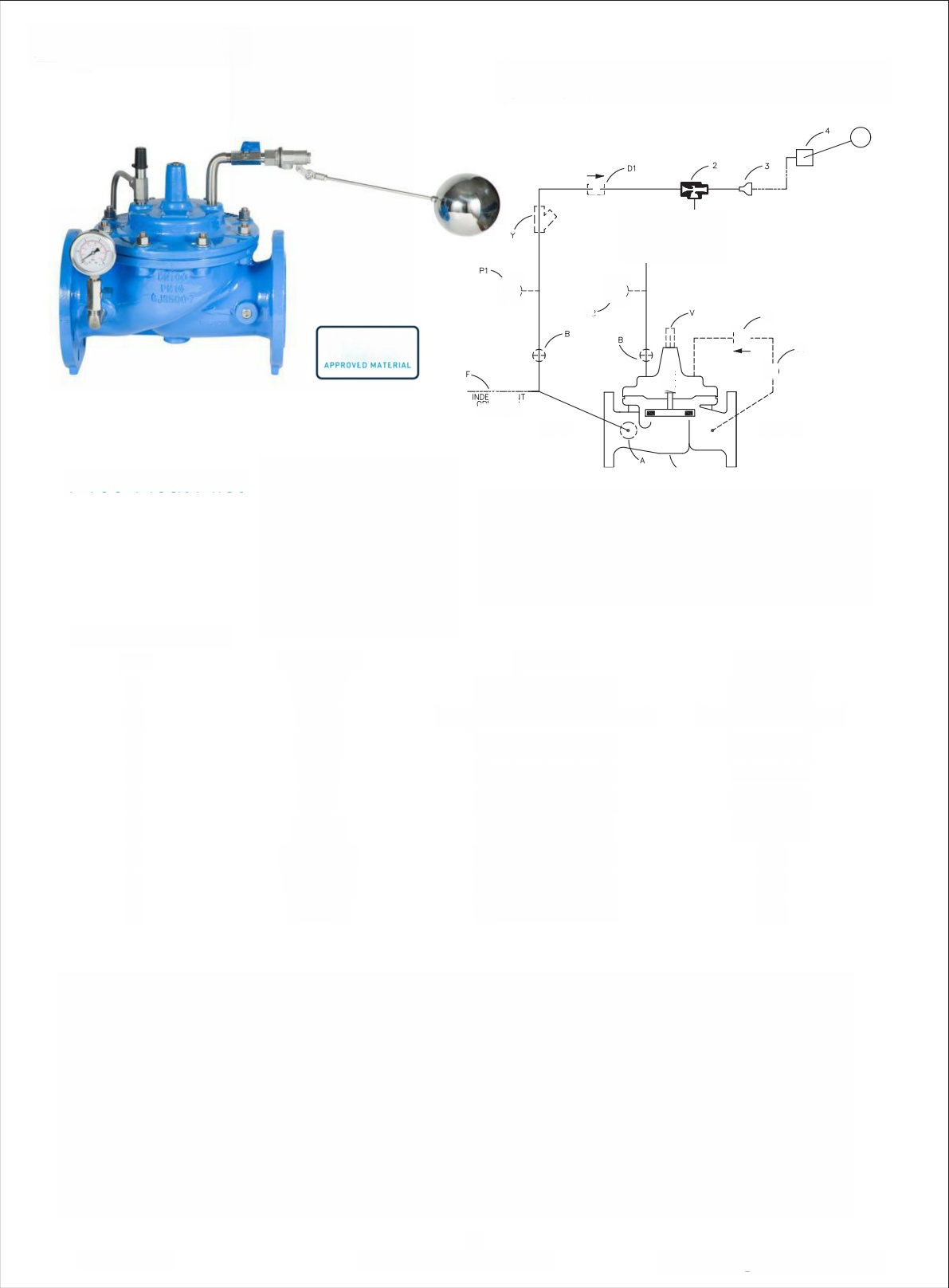

S100X-16

SHSUOTE

S100X Float control valve

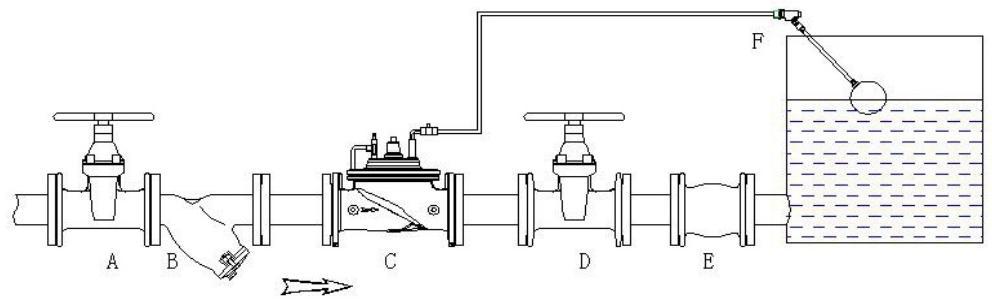

P100-Float Pilot

Part List &Material

1 | Body | Stainless Steel | AISI304 |

2 | Disc | StainlessSteel+Rubber | AISI304+EPDM |

3 | Yoke | Stainless Steel | AISI 304 |

4 | Rod | Stainless Steel | AISI304 |

5 | Nut | Stainless Steel | AISI304 |

6 | Float | Stanless Steel | AISI304 |

7 | Jam Nut | Stainless Steel | A2 |

8 | Bonnet | Stainless Steel | A2 |

9 | Screw | Stainless Steel | A2 |

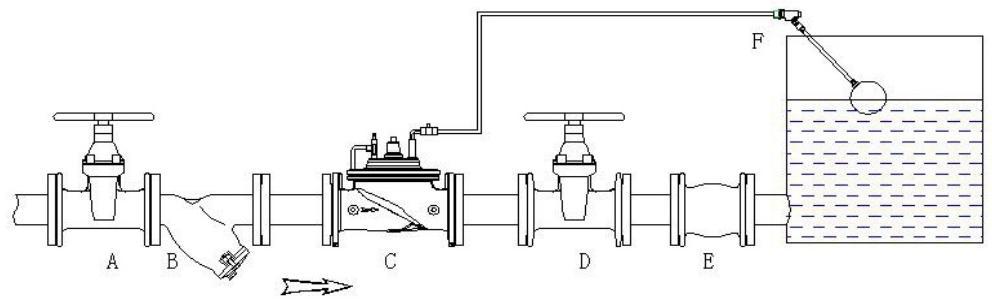

The working principle of float valves is based on buoyancy and lever principles. When the liquid level in the container changes, the float will rise or fall accordingly, and the opening or closing of the valve is controlled by lever action. Specifically, when the liquid level is below the set value, the float descends, driving the valve to open and allowing the liquid to flow into the container; When the liquid level reaches the set value, the float rises and drives the valve to close, stopping the flow of liquid. Characteristics and application scenarios of different types of float valves Pipeline floating ball valve: Automatic water inlet and automatic shut-off, commonly used in water tanks or pools to maintain a constant water level. Suitable for diameters of 15-100mm, easy to install, high sensitivity to use, low head loss, and no water hammer phenomenon. Floating ball regulating valve: Used to control the liquid level in the container and maintain a certain liquid level height. Commonly used for liquid level control of low-pressure vessels, suitable for various industrial applications. Float switch: Used to control the operation of pumps, automatic loading and unloading of tanks, liquid level supply signals, etc. Using magnetic operation without mechanical connectors, the operation is simple and reliable.

S100X Float control valve

P100-Float Pilot

Part List &Material

1 | Body | Stainless Steel | AISI304 |

2 | Disc | StainlessSteel+Rubber | AISI304+EPDM |

3 | Yoke | Stainless Steel | AISI 304 |

4 | Rod | Stainless Steel | AISI304 |

5 | Nut | Stainless Steel | AISI304 |

6 | Float | Stanless Steel | AISI304 |

7 | Jam Nut | Stainless Steel | A2 |

8 | Bonnet | Stainless Steel | A2 |

9 | Screw | Stainless Steel | A2 |

The working principle of float valves is based on buoyancy and lever principles. When the liquid level in the container changes, the float will rise or fall accordingly, and the opening or closing of the valve is controlled by lever action. Specifically, when the liquid level is below the set value, the float descends, driving the valve to open and allowing the liquid to flow into the container; When the liquid level reaches the set value, the float rises and drives the valve to close, stopping the flow of liquid. Characteristics and application scenarios of different types of float valves Pipeline floating ball valve: Automatic water inlet and automatic shut-off, commonly used in water tanks or pools to maintain a constant water level. Suitable for diameters of 15-100mm, easy to install, high sensitivity to use, low head loss, and no water hammer phenomenon. Floating ball regulating valve: Used to control the liquid level in the container and maintain a certain liquid level height. Commonly used for liquid level control of low-pressure vessels, suitable for various industrial applications. Float switch: Used to control the operation of pumps, automatic loading and unloading of tanks, liquid level supply signals, etc. Using magnetic operation without mechanical connectors, the operation is simple and reliable.