- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

S100B-16

SHSUOTE

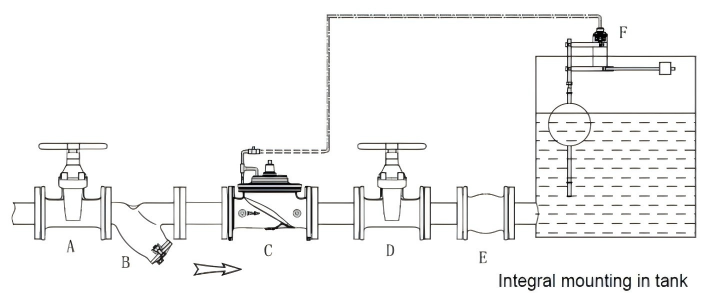

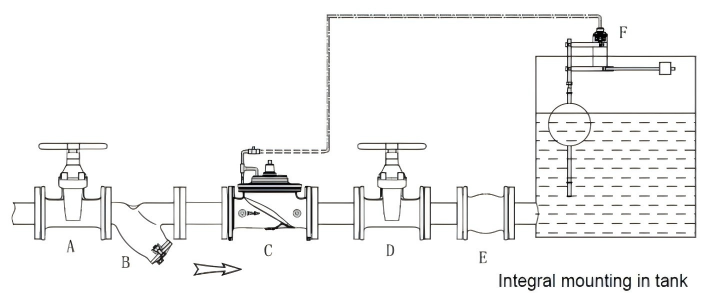

The working principle of the liquid level control float valve is mainly based on the principle of buoyancy. When the water level rises, the float rises and pushes the valve to close through the valve stem, preventing fluid from continuing to flow in; When the water level drops, the float descends and the valve opens, allowing fluid to flow in. This process achieves automatic control of water level. Structure and composition of float valve Floating ball valve is mainly composed of floating ball, valve stem, valve and connecting pipeline. The design of the floating ball should ensure stable operation at different water levels, without being affected by external factors. Application scenarios and advantages of float valves Floating ball valves have the following advantages in automatic water level control: 1. Automatic adjustment: Automatically adjust the opening and closing of the valve according to changes in water level, without the need for manual intervention. 2. Precise control: High sensitivity and accuracy, avoiding excessive or insufficient water filling. 3. Energy saving and efficient: By automatically controlling the water level, energy is saved and water resource waste is reduced. 4. Safety assurance: In certain applications, such as boiler water level control, safety accidents caused by high or low water levels are prevented. Float valves are widely used in various scenarios that require automatic water level control, such as shipbuilding, papermaking, printing, generator equipment, petrochemicals, food industry, water treatment, electrical engineering, dye industry, hydraulic machinery, and other fields

The working principle of the liquid level control float valve is mainly based on the principle of buoyancy. When the water level rises, the float rises and pushes the valve to close through the valve stem, preventing fluid from continuing to flow in; When the water level drops, the float descends and the valve opens, allowing fluid to flow in. This process achieves automatic control of water level. Structure and composition of float valve Floating ball valve is mainly composed of floating ball, valve stem, valve and connecting pipeline. The design of the floating ball should ensure stable operation at different water levels, without being affected by external factors. Application scenarios and advantages of float valves Floating ball valves have the following advantages in automatic water level control: 1. Automatic adjustment: Automatically adjust the opening and closing of the valve according to changes in water level, without the need for manual intervention. 2. Precise control: High sensitivity and accuracy, avoiding excessive or insufficient water filling. 3. Energy saving and efficient: By automatically controlling the water level, energy is saved and water resource waste is reduced. 4. Safety assurance: In certain applications, such as boiler water level control, safety accidents caused by high or low water levels are prevented. Float valves are widely used in various scenarios that require automatic water level control, such as shipbuilding, papermaking, printing, generator equipment, petrochemicals, food industry, water treatment, electrical engineering, dye industry, hydraulic machinery, and other fields