- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

S300X-16

SHSUOTE

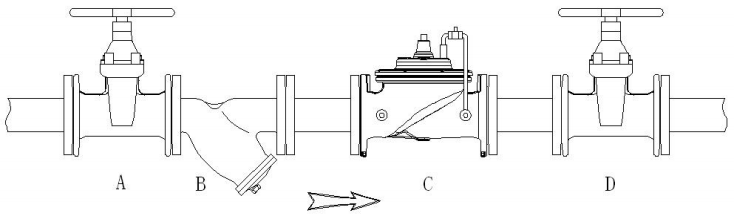

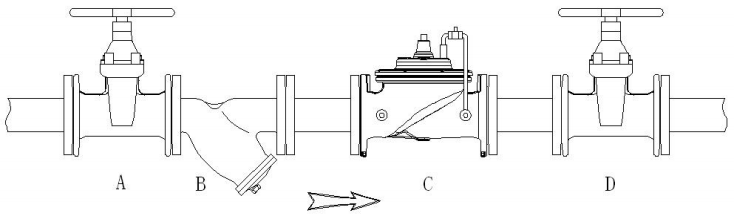

Slow closing check valve is an intelligent valve installed at the outlet of water pumps in high-rise building water supply systems and other water supply systems to prevent medium backflow, water hammer, and water hammer phenomena. This valve combines the functions of an electric valve, a check valve, and a water hammer eliminator, effectively improving the safety and reliability of the water supply system. It also integrates the technical principles of slow opening, quick closing, and slow closing to eliminate water hammer, preventing the occurrence of water hammer when starting or stopping the pump.

Structural features:

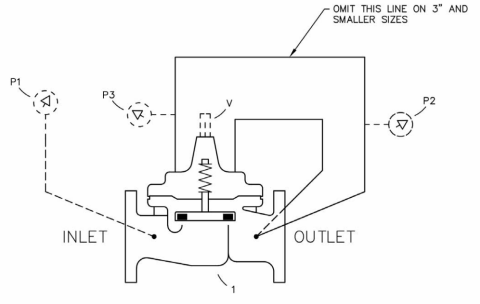

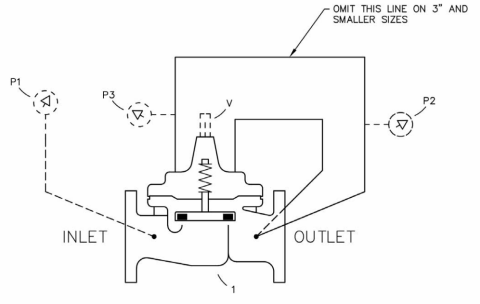

The 300X slow closing check valve consists of a main valve, a one-way valve, a needle valve, a ball valve, a micro filter, and a pressure gauge to form a hydraulic control connection system. By utilizing hydraulic automatic operation, the main valve can achieve the optimal opening or closing speed. To prevent the occurrence of water hammer and achieve the effect of slow closing and noise reduction. This product utilizes hydraulic self control, does not require other devices or energy, is easy to maintain, and has smooth opening and slow closing. This series of valve products is widely used in water supply network systems such as high-rise buildings and living areas, as well as urban water supply projects.

working principle:

When the valve supplies water from the inlet end, the water enters the main valve control room through a micro filter, needle valve, and one-way valve, and then drains downstream through a ball valve. Because the opening of the needle valve is smaller than that of the ball valve, that is, the drainage speed of the main valve control room is greater than the inlet speed, the pressure in the control room decreases, and the inlet pressure acting on the lower end of the main valve disc opens the main valve to supply water downstream. When the pipeline stops supplying water, if the downstream water starts to flow back, a portion of the return water enters the main control room through the ball valve. Due to the action of the one-way valve, the return water cannot flow out of the main control room, causing the main control room to gradually increase pressure and slowly close the main valve.

Slow closing check valve is an intelligent valve installed at the outlet of water pumps in high-rise building water supply systems and other water supply systems to prevent medium backflow, water hammer, and water hammer phenomena. This valve combines the functions of an electric valve, a check valve, and a water hammer eliminator, effectively improving the safety and reliability of the water supply system. It also integrates the technical principles of slow opening, quick closing, and slow closing to eliminate water hammer, preventing the occurrence of water hammer when starting or stopping the pump.

Structural features:

The 300X slow closing check valve consists of a main valve, a one-way valve, a needle valve, a ball valve, a micro filter, and a pressure gauge to form a hydraulic control connection system. By utilizing hydraulic automatic operation, the main valve can achieve the optimal opening or closing speed. To prevent the occurrence of water hammer and achieve the effect of slow closing and noise reduction. This product utilizes hydraulic self control, does not require other devices or energy, is easy to maintain, and has smooth opening and slow closing. This series of valve products is widely used in water supply network systems such as high-rise buildings and living areas, as well as urban water supply projects.

working principle:

When the valve supplies water from the inlet end, the water enters the main valve control room through a micro filter, needle valve, and one-way valve, and then drains downstream through a ball valve. Because the opening of the needle valve is smaller than that of the ball valve, that is, the drainage speed of the main valve control room is greater than the inlet speed, the pressure in the control room decreases, and the inlet pressure acting on the lower end of the main valve disc opens the main valve to supply water downstream. When the pipeline stops supplying water, if the downstream water starts to flow back, a portion of the return water enters the main control room through the ball valve. Due to the action of the one-way valve, the return water cannot flow out of the main control room, causing the main control room to gradually increase pressure and slowly close the main valve.