- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

S600X-16

SHSUOTE

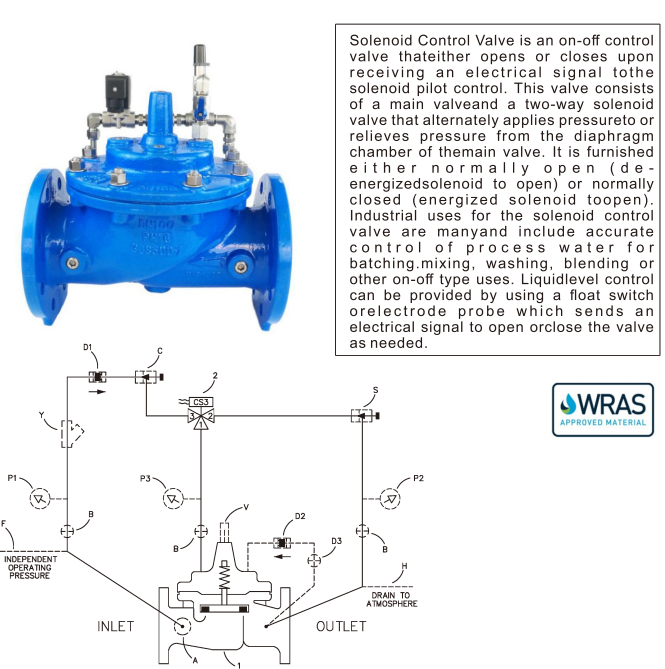

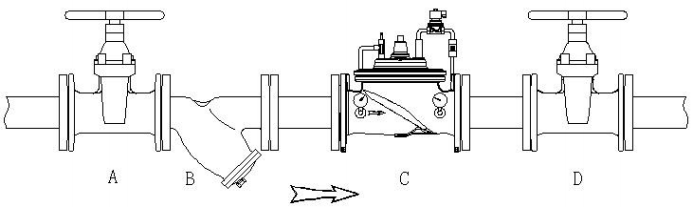

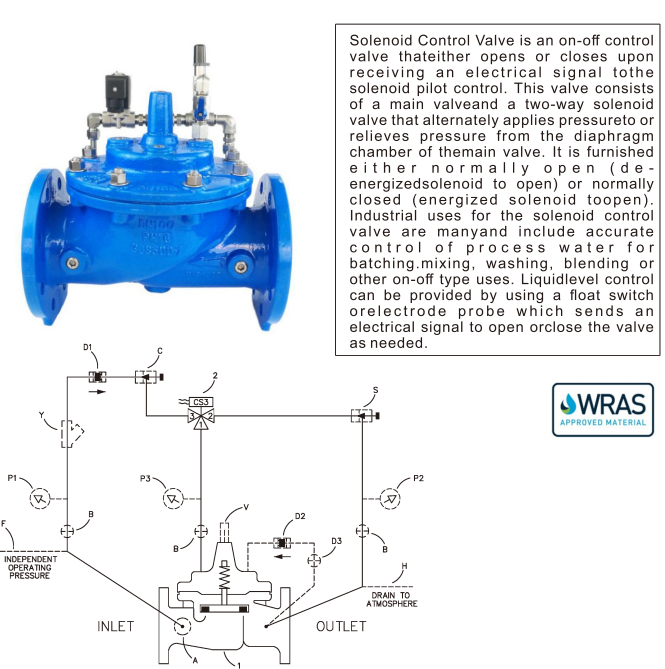

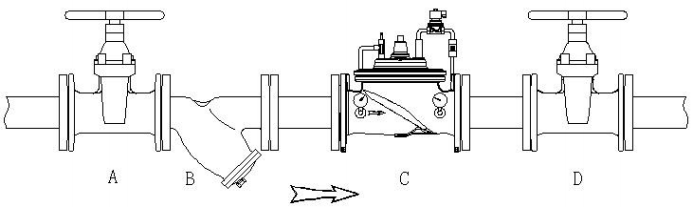

The electric control valve S600X is a hydraulic operated valve with an electromagnetic valve as the guide valve, commonly used for automatic control in water supply, drainage, and industrial systems. Its working principle is based on the control of solenoid valves, which remotely open and close the pipeline system through electrical signals, achieving remote operation.

1. Opening process: When the solenoid valve is powered on, it opens and the water in the control room flows out through the solenoid valve and ball valve, causing a decrease in pressure in the upper chamber of the main valve diaphragm. Under the pressure difference, the medium pushes open the main valve core, the main valve opens, and water supply begins. 2. Closing process: When the solenoid valve is powered off, the solenoid valve closes, and the outlet of the upper chamber of the main valve diaphragm is closed. The pressure in the upper chamber of the diaphragm increases, pushing the diaphragm to close the main valve and stop water supply. Adjustment function: The needle valve can adjust the closing time of the main valve. Clockwise rotation of the needle valve can extend the closing time of the main valve, while counterclockwise rotation can shorten the closing time.

The electric control valve S600X is a hydraulic operated valve with an electromagnetic valve as the guide valve, commonly used for automatic control in water supply, drainage, and industrial systems. Its working principle is based on the control of solenoid valves, which remotely open and close the pipeline system through electrical signals, achieving remote operation.

1. Opening process: When the solenoid valve is powered on, it opens and the water in the control room flows out through the solenoid valve and ball valve, causing a decrease in pressure in the upper chamber of the main valve diaphragm. Under the pressure difference, the medium pushes open the main valve core, the main valve opens, and water supply begins. 2. Closing process: When the solenoid valve is powered off, the solenoid valve closes, and the outlet of the upper chamber of the main valve diaphragm is closed. The pressure in the upper chamber of the diaphragm increases, pushing the diaphragm to close the main valve and stop water supply. Adjustment function: The needle valve can adjust the closing time of the main valve. Clockwise rotation of the needle valve can extend the closing time of the main valve, while counterclockwise rotation can shorten the closing time.